Introduction

Printegrity Group is a combined marketing and print production facility with more than 25 years’ experience. They supply point of sale and display to the advertising, retail and industrial sectors.

The Challenge

When Steve Broughton found himself working in the funeral industry during COVID, he quickly identified a major problem – traditional cardboard coffins were difficult to assemble, inefficient, and unreliable. The coffins sourced from a Sydney supplier were problematic –

- Time-consuming assembly: It took two people five minutes to put one together.

- Cumbersome hardware: Plastic screws made the process frustrating.

- Unreliable supply chain: Deliveries were consistently delayed.

Determined to create a better solution, Steve designed a self-locking coffin that simplified the process. However, his supplier couldn’t keep up with demand. He needed a reliable manufacturing partner who could refine the design and deliver on time. So, he turned to Production Packaging Innovations.

Solution: A Collaborative and Adaptive Approach

Steve reached out to Almanzo at PPI, and from the first meeting, he noticed a difference. Unlike his previous supplier, PPI took a consultative and solutions-driven approach, refining his design instead of just replicating it.

What PPI Delivered:

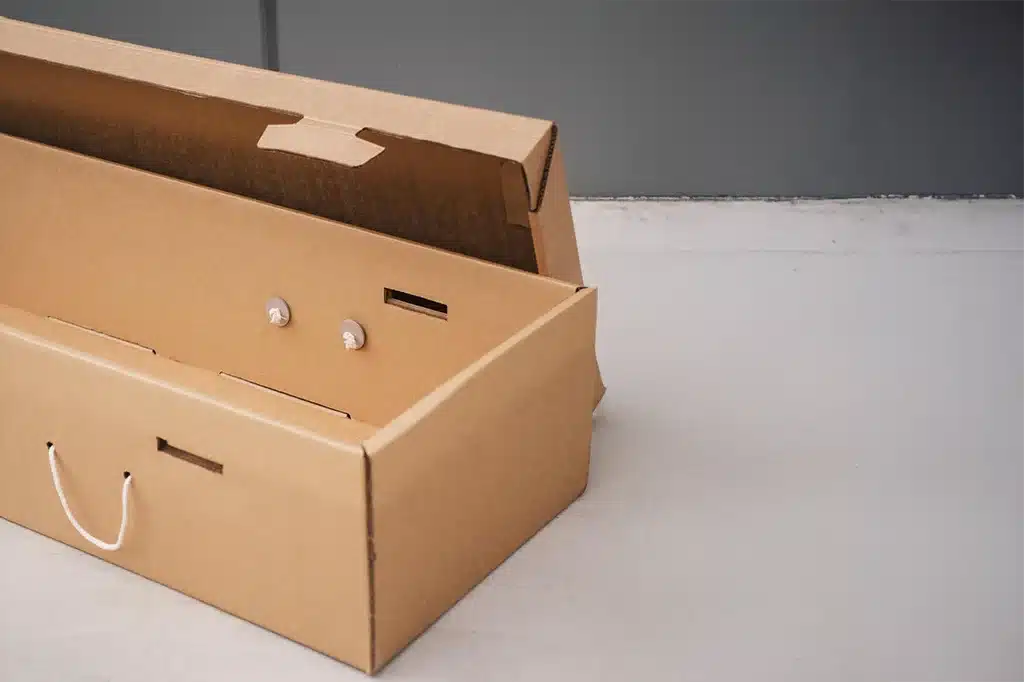

- Smart design improvements: PPI’s in-house prototyping team enhanced Steve’s original concept, creating a self-locking coffin that removed the need for screws altogether.

- Faster assembly: The new design allowed a single person to assemble it in just a couple of minutes – a significant improvement.

- Reliability & consistency: Unlike his previous supplier, PPI ensured on-time delivery, providing a dependable stockholding service.

- Eco-friendly materials: PPI’s sustainable packaging solutions aligned with Steve’s commitment to reducing waste.

“When I visited PPI’s factory, we had in-depth discussions about what I needed. Instead of just making exactly what I asked for, they worked with me to improve it. That collaborative approach made all the difference.” – Steve Broughton, Printegrity

The Result

With PPI’s expertise, Steve was able to launch a superior cardboard coffin that solved the key issues his team had faced. The new design was a time-saver. Thanks to its self-locking feature, assembly is quick and hassle-free. The funeral transport team has had zero complaints, marking a significant improvement. Additionally, PPI’s reliable supply chain ensures on-time deliveries, while our responsive service provides ongoing support and quick resolutions to any concerns.

“The new design is great—easier, faster, and way more efficient. The team doesn’t have any issues with it, which is a big win.” – Steve Broughton

Following the success of the cardboard coffin, Steve is now working with PPI on a new product line – eco-friendly pet coffins. PPI has already produced prototypes, and Steve is confident there’s a market for it.

Recent case studies

Case study

Wrapped in Wonder: The Packaging Behind the Charlie Bears Charm

Introduction Charlie Bears has been enchanting collectors for 20 years with their lovingly handcrafted bears. Founded in the UK by Charlie herself, th...

More

Case study

Reinventing the Cardboard Coffin with Smart Design

Introduction Printegrity Group is a combined marketing and print production facility with more than 25 years’ experience. They supply point of sale ...

More

Case study

Custom Packaging for Unique Gift Hampers

Beyond the Wooden Door is a mother-daughter business based in Melbourne with over 15 years of experience creating unique, consciously made gift hamper...

More