Cut Costs & Returns with Heavy-Duty Protective Packaging

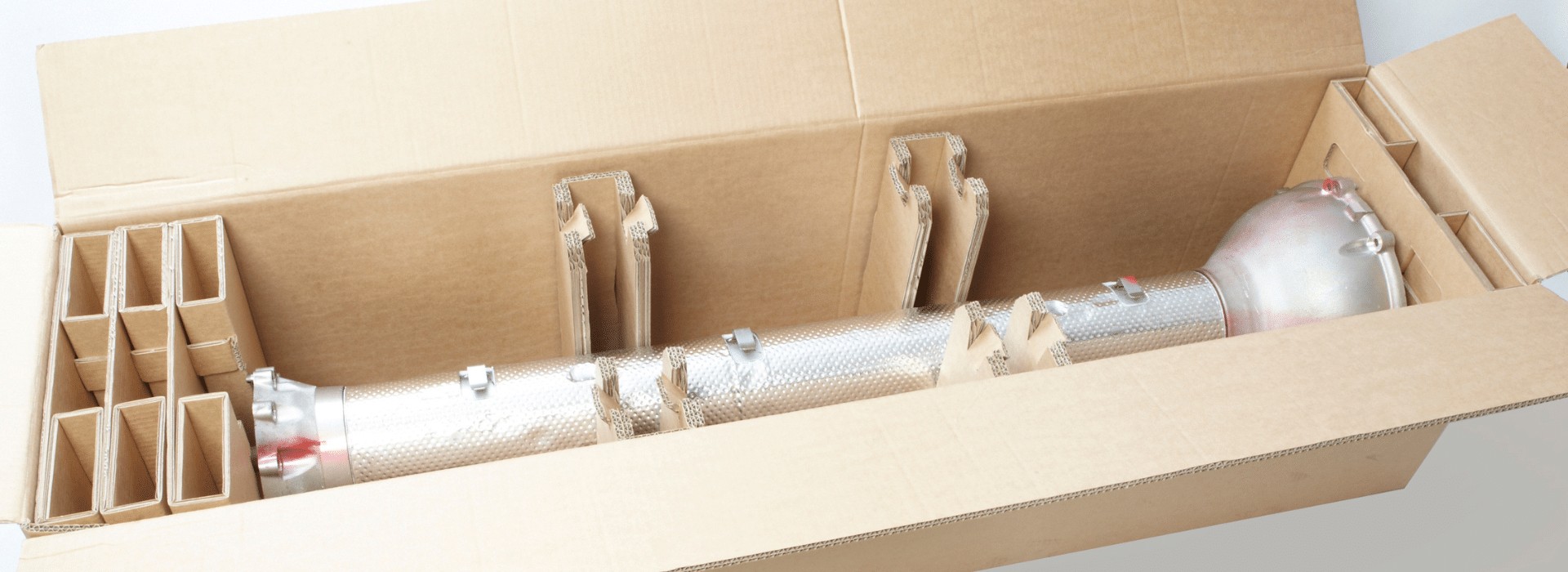

At Production Packaging Innovations (PPI), we get it – shipping can be rough. That’s why we’ve engineered cardboard protective packaging that stands up to the challenge. Whether you’re sending fragile items, electronics, or bulky goods, our packaging ensures your products arrive in perfect condition, even the most oddly shaped ones.

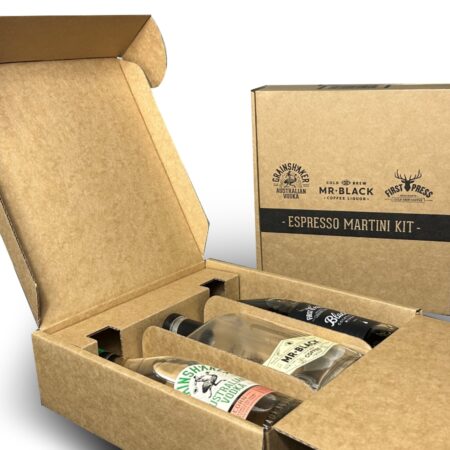

Protective packaging is a form of insurance. The primary goal is to prevent product damage, and by doing so, you save on unnecessary costs and protect your brand image. Our packaging also enhances the unboxing experience transforming a simple box into an extension of your brand’s personality, creating a delightful unboxing experience that makes them feel connected to your brand.

When it comes to protective packaging, we’re the experts.

PPI has been helping Aussie businesses with custom packaging solutions since 1980. Over the years, we’ve built a talented team of specialist designers, engineers, and technicians who bring a wealth of knowledge and a creative, problem-solving mindset to every project. Our goal is simple – to ensure your products arrive at their destination without any unexpected surprises. We don’t just protect your products; we elevate your brand reputation.

Request a consultation with us today to find out how our expert team can provide the perfect packaging solution for your product.

Why Our Cardboard Protective Packaging is a Smart Choice

- Excellent cushioning for durability & shock absorption in transit

- Custom inserts to fit a variety of products for a snug & secure fit

- Made from recyclable materials to reduce environmental impact

- Reliable protection at an affordable price

- A proactive and strategic way to protect your brand reputation

- Enhances your customer’s unboxing experience

Tailored Protective Packaging for Every Business

Whether you’re shipping artisanal candles from your home studio or managing large-scale product distribution, our protective packaging is designed to cater to your specific requirements. Let us help you create a packaging solution that reflects your business values and protects what matters most.

Important Considerations for Customised Protective Packaging

Custom protective packaging works best when it’s designed with your product in mind. Bulky, heavy items need sturdy solutions, while delicate goods require extra cushioning. Every product is different, so your cardboard protective packaging should be too.

Pick the right materials

Whether it’s make-up, food, dish cleaning liquid, or furniture – each item has unique packaging needs. The right protective packaging material ensures your products are protected from environmental factors and impacts during transport.

There is no one-size-fits-all solution. For example, fresh produce needs breathable, moisture-resistant packaging to maintain its quality, while fragile electronics require sturdy, shock-absorbing materials to prevent damage in transit. The right choice makes all the difference in getting your product safely to its destination.

At PPI, we specialise in creating sustainable packaging that gives your products the protection they need without harming the planet.

Be specific about product specifications

Getting the right fit is key. Too much space leads to wasted materials and unnecessary movement. Most successful protective packaging designs fit the product as snug as a glove.

Providing accurate measurements allows our designers to create packaging that keeps your product secure without excess or too little space. With the right cardboard protective packaging, your products stay safe, your customers stay happy, and your brand stays strong.

Types of protective packaging

- Standard style shipper cartons

- Fully customised cut to shape boxes

- Product specific inserts

- Protective inserts

- Branded or plain

Order Your Cardboard Protective Packaging Today

Don’t leave your shipments to chance. Explore our collection of cardboard protective packaging or talk to our team about personalised recommendations. We’re ready to help you find the perfect packaging solution for your business.

Our work

Brands we’ve worked with

Protective packaging case studies and articles

Case study

IXL Appliances

IXL Appliances is an industry leader and innovator in home appliances. Since 1858, IXL has been synonymous with the highest quality heat, light and ve...

More

Case study

Case Study – Ned Australian Whisky

Ned Australian Whisky is an Australian whisky for everyone. Born from a desire to create a locally crafted whisky that’s unqiuely Australian, Ned Wh...

More

Article

5 Protective Packaging Tips for Your Products

In a world where leaving a product review is only a few clicks away from a smartphone, it’s vital for your products to arrive on your consumers’ d...

More

Frequently Asked Questions

Cardboard protective packaging involves using cardboard materials to provide durable, shock-absorbing layers that keep your items safe from damage. It includes items like corrugated boxes, cardboard inserts, and void fillers that offer high-quality protection during shipping and storage.

Cardboard is cost-effective, versatile, and environmentally friendly. It provides superior cushioning for any product, from electronics to household items, ensuring your items are protected through long-distance transport and constant shipping and handling.

There are several types of cardboard protective packaging, including single-walled and double-walled cardboard boxes, and fibre drums. Each type offers different levels of protection and is suitable for various products.

Cardboard packaging protects products by providing structural integrity and cushioning, using corrugated layers to provide a springy protective barrier against bumps, drops, and other hazards during transit and handling.

Yes, cardboard packaging is recyclable. It’s an environmentally friendly option that can be repurposed or recycled, reducing waste and your carbon footprint.

Cardboard packaging can be customised with additional cushioning materials like air pillows or foam inserts to provide extra protection for fragile items.

Consider factors like the size, weight, and fragility of your product. You’ll also want to think about the shipping conditions and whether you need additional cushioning or void fillers.

Absolutely! Well-designed cardboard packaging can take the unboxing experience to the next level by combining durability with style. Thoughtful touches like easy-to-open features, neat compartments, and captivating visuals turn the simple act of opening a package into an exciting moment. It’s not just about protection but also creating a memorable experience that encourages repeat purchases.

Investing in quality cardboard packaging shows your commitment to quality, sustainability, and customer experience. A positive first impression is important for building brand loyalty and trust.

Yes, using the right protective packaging to wrap and cushion ensures the product remains safe and secure against external damages. Inserts are used to help keep items in place and prevent unnecessary movement. These elements help businesses save on costs of damaged products and meet customer satisfaction.

Depending on the packaging needs of the product and environmental concerns, custom packaging designs are created using a range of materials like corrugated cardboard, moulded pulp, air pillows, bubble wrap, and foam.

Branding is essential in protective packaging because it transforms a simple box into an extension of your brand’s personality. Eye-catching designs and logos not only help customers easily recognise their favourite products but also creates a memorable unboxing experience that makes them feel connected to your brand. Thoughtful branding can elevate the perceived value of your product, turning packaging into a powerful marketing tool that encourages repeat purchases and shareability.