Havens Kitchen (Laminex) – Stylish Kitchens Made quick and Easy

Havens Kitchen brings simplicity, convenience, speed and good old Aussie know-how to your kitchens through their cutting-age and market leading pre-assembled kitchen solutions.

Havens Kitchen believe the kitchen is the focal point of the home – a place to be together and bond with your loved ones. Therefore, it should be designed for easy navigation within a collaborative space. This allows you to enjoy an on-trend, high-quality kitchen experience with your friends and family.

Kitchen Haven offers all inclusive, first-of-its-kind kitchen cabinets in Australia – designed and built to get your new kitchen up and running, quickly! This includes appliances, sinks, taps, handles etc.

The Brief

Laminex is an important client of Kitchen Haven, manufacturing panels that are included in the high-quality kitchen cabinets they produce. These panels are an essential part of their range of offerings – allowing tradesmen to efficiently gather all essential components of the kitchen plan in under thirty minutes at any Haven Hub. Such as door panels, carcasses, base and wall units, including white goods.

As such it was challenging to find packaging solutions that were easy to assemble, cost-effective and at the same time could be used for the wide range of panels and skews.

The Process

We collaborated with Haven Kitchen every step of the way, taking several trips to Ballarat to collect samples to trial our designs in situ and test performance during delivery.

Our expertise in packaging and design allowed us to create a solution to fit all Laminex’s requirements – efficient, effective, and protective.

There were around thirty different products in the range, for which we created samples and converted into packaging solutions, gaining final approval and complete satisfaction from the Laminex team.

The Challenge

To create packaging for over 30 products, in a cost-effective manner with additional requirements to ensure the packaging displays the products and is easy for the handling team to pack/unpack.

To remain competitive, it was also important for the packaging costs to be minimal.

At first, the client wanted a standardised design that could be applied across all products to minimise the complexity and number of designs required.

However, they soon decided to create individual packaging for each product to simplify the work for their handling team. PPI sampled designs for over 30 products, which made the process more challenging for us.

Since this was a first for Laminex, it was our responsibility to guide them and help them make packaging decisions that would be beneficial for their business in the short and long term.

We project managed the design and trial phase of the packaging, to create a total packaging solution, without impacting our client’s otherwise hectic schedules.

The Solution

We started by collecting samples of the products and customised unique door and panel wraps which provided the first layer of protection for panels.

We also worked on samples of more complex components, such as cabinets to create custom solutions for each product.

To protect the packaging from damage during transit, such as scratching and/or collapsing of the edges, we used corrugated cardboard as the primary material for all packaging. Corrugated cardboard excels in strength-to-weight ratio, positioning it as the optimal choice for packaging and protecting products during transit. Its inherent rigidity enables it to withstand substantial weight and pressure, especially when boxes are stacked during shipping. Additionally, the layers of corrugated cardboard offer flexibility, making it an excellent choice for securely wrapping individual items.

Features:

- Optimal Product Protection: the new packaging offers the utmost support and protection to the products to avoid costs of damage during transit.

- Easy and Efficient Handling: Easy assembly simplifies the process of packing heavyweight and oversized products for the operations and logistics teams.

- Brand Building: Ensuring the product arrives undamaged at its destination, helps businesses establish a reputation for reliability from the get-go.

Recent case studies

Case study

Custom Packaging for Unique Gift Hampers

Beyond the Wooden Door is a mother-daughter business based in Melbourne with over 15 years of experience creating unique, consciously made gift hamper...

More

Case study

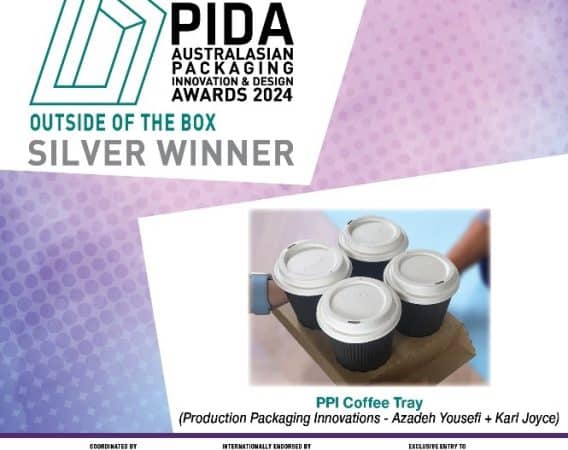

PPI’s PIDA Nominate Coffee Trays – changing and safeguarding the way of takeaway coffee

Coffee has kept up with the changing lifestyle and commuter culture which demanded and (therefore) led to the invention of cardboard coffee holder tra...

More

Case study

Beyond the Buzzwords: Ace your Custom Packaging Design for Success

In times when shopping and retail are going through a massive digital transition, customers have access to more retailers than ever before. ...

More