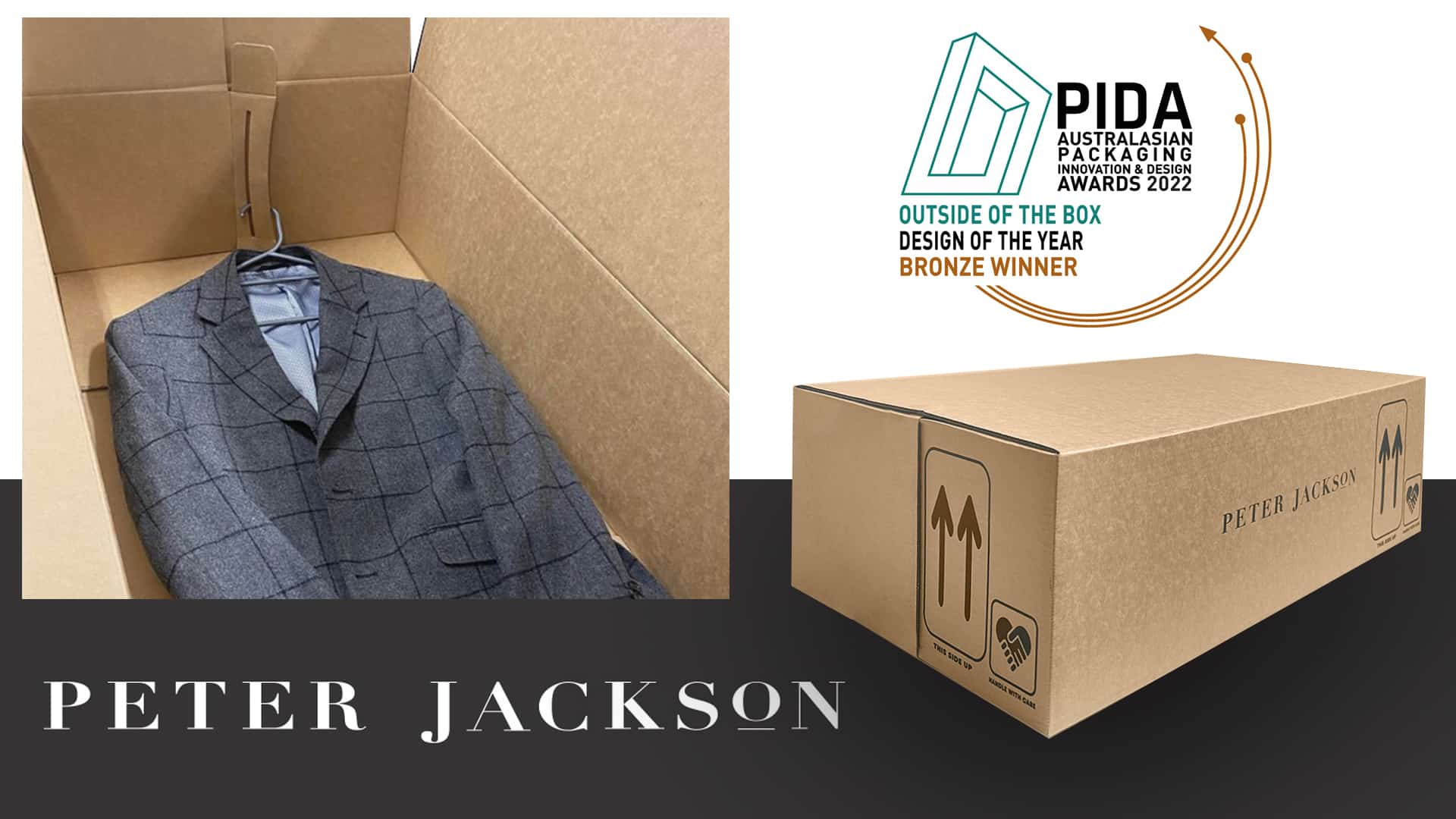

Peter Jackson – Revolutionising Menswear Clothing in Retail Space

Peter Jackson is a widely known menswear clothing brand in Australia. Their garments are crafted with innovative designs and superior-quality execution. To make fashion and luxury accessible to everyone, their business thrives to revolutionize men’s clothing in the retail space. They aim to deliver world-class clothing, made with the finest textiles to the modern man – without having to pay over the odds.

The Brief

The average ticket price at Peter Jackson is slightly on the higher end, somewhere upwards of the $400-$600 range. During the client workshops, we understood that they essentially needed packaging that could protect and guard the high-end clothing during transit – especially between warehouses and stores. This is of absolute importance to Peter Jackson, to deliver on their promise to the customers and maintain the brand image they have established over the years.

The Solution

We created for Peter Jackson, a customer garment box. Based on a regular slotted carton (RSC_ FEFCO 0201 (two-piece RSC with an extended glue flap).

Each component, when assembled, makes up the side wall panel, base, and top panel. When two components are glued in the middle at the top and bottom – it becomes the regular slotted carton with inbuilt hanger flaps.

The box itself is constructed from BE flute corrugated board, known for its exceptional strength, ensuring the creation of a durable hanger flap that maintains its integrity throughout the shipping process. The box can hold up to 12 tailored suits, without crushing. The new design minimizes the potential movement inside the box during transportation, thus, preserving the products’ quality and condition.

Features

Functionality

The bespoke garment box is easy to handle by design, therefore, it is convenient to use in the fast-paced manufacturing/logistics environment. The structure can be neatly assembled/disassembled, hence, minimizing the occurrences of damage and significantly reducing the costs for Peter Jackson.

The previous packaging could only hold up to three garments. Additionally, they were encountering frequent damage during transportation. This often resulted in delays, as the company could not afford to deliver the products with below-standard presentation to their high-end clientele.

With the new packaging, designed and produced by PPI, Peter Jackson was happy to report next to no damages during transit. The garments remained well guarded for the entire duration, from manufacturing to delivery to the client and through the many stops in between. Additionally, the new box can hold up to 12 garments without compromising the pristine condition of the clothes. This is four times the capacity of the previous box.

Peter Jackson is now able to get far more value out of their deliveries, the new packaging has significantly reduced their packaging costs without any compromise in the quality. While the clothes always reach the customer, stores or warehouses with the utmost perfection intended.

Innovation

Most garment boxes that exist in the market or are used by competitors come with either metal hanging rods, elastic fabric strips, or glued cardboard flaps on the inside. These solutions are labor-intensive, thus, costly or unsustainable. The flaw of these designs, do not allow the boxes to carry up to 12 products – damage-free during transit.

Our team of expert designers, using our state-of-the-art CAD drawing equipment, put together a solution that would strengthen PJ’s position as a market leader and give them an advantage over competitors.

No other business in this industry uses a solution like our bespoke garment box, however, it is likely to become popular in the coming times as more businesses adapt their packaging along similar lines to PJ.

Currently, Peter Jackson holds the monopoly in the market to securely transport an increased amount of products in one delivery. This has enabled them to sell more products, meeting all quality standards and customer expectations. Hence, allowing them to keep dominating the menswear retail space and maintain their healthy brand reputation.

Sustainability

Peter Jackson has been making changes within, to switch to a more sustainable way of conducting the business. The bespoke packaging garment box we designed and produced for Peter Jackson is 100% recyclable and comes without any single-use plastic rods that existed in the previous design. It is made of FSC-certified material, this design excludes any unnecessary materials from the previous design which were not environmentally friendly. This aligns the brand with Australia’s sustainability goals, on track to be achieved by 2023.

Recent case studies

Case study

Reinventing the Cardboard Coffin with Smart Design

Introduction Printegrity Group is a combined marketing and print production facility with more than 25 years’ experience. They supply point of sale ...

More

Case study

Custom Packaging for Unique Gift Hampers

Beyond the Wooden Door is a mother-daughter business based in Melbourne with over 15 years of experience creating unique, consciously made gift hamper...

More

Case study

PPI’s PIDA Nominate Coffee Trays – changing and safeguarding the way of takeaway coffee

Coffee has kept up with the changing lifestyle and commuter culture which demanded and (therefore) led to the invention of cardboard coffee holder tra...

More