Unidrive’s Journey to Streamlined & Recyclable Packaging

Unidrive is an established manufacturer of automotive driveline componentry and equipment. The company has a history dating back as far as 1953, supplying parts across the automotive, mining, transport, agricultural and civil construction industries. One of Unidrive’s main clients over the years included GM Holden in the USA. Unidrive provided the company with large driveline components for their iconic Corvette vehicle. Precious cargo!

Univdrive’s Packaging Challenge

“We sought a packaging partner to design and manufacture cardboard packaging that would ensure our supplies were able to be packed in a safe and ergonomic manner… We also needed to guarantee that our precision parts were protected from any kind of damage.”

– Jon Strachan, Unidrive

Unidrive were in urgent need of upgrading their current packaging for their componentry. While previously they used foam and HDPE plastic trays so that their supplies could withstand overseas freight to the U.S.A with complete protection, their client GM Holden suddenly requested that all packaging moving forward must be recyclable. This necessitated the need for eco-friendly as well as economic materials, throwing a major spanner in the works for their business partnership, putting pressure on Unidrive to quickly find a durable solution.

To accommodate GM Holden’s latest request, Unidrive attempted putting together sustainable sea freight packaging with various companies, but each failed to meet the specifics of Unidrives packaging brief; to find a solution that is cost-effective, protective and recyclable.

Unidrives supplies and componentry were large and heavy (such as large torque tubes and prop shafts) and were proving difficult to transport using only sustainable materials. The new packaging needed to be designed to ensure the optimal density and number of parts was able to be packed into a shipping container.

Unidrive turned to PPI in hopes of finding a more environmentally-friendly solution; one that would eliminate their current foam and HDPE plastic trays in order to maintain their ongoing work with GM Holden.

PPI’s Customised Solution

The project objectives were clear, but challenging given the size, weight and scale of Unidrive’s parts range. The only way to ensure Unidrive’s packaging needs were met was through creating multiple packaging prototypes. PPI meticulously designed and engineered several versions to achieve the best result for the project.

After each packaging test, PPI prepared new design modifications and consulted Unidrive with suggestions, taking on board their feedback from each round.

As Jon Strachan from Unidrive explains, “We used production samples to do several shipments in real life shipments via sea freight to the client in the USA, and then sought feedback and adjusted the solution accordingly.” The whole process relied upon a collaborative approach between Unidrive, GM Holden and PPI’s logistics packaging design team, to ensure that the very best solution was found.

The Result

PPI succeeded in designing and engineering a state-of-the-art packaging solution that was both cost effective and recyclable.

“The design was clever and practical. Not only did PPI eliminate foam packaging, making our business far more environmentally friendly, but we achieved an incredible 20% reduction in packaging costs.”

“Working with the PPI team was easy, transparent, collaborative and communication was timely. Nothing was ever too much trouble for PPI.”

– Jon Strachan, Unidrive

It was a project that challenged the boundaries of what could be achieved in cardboard as a medium, whilst also working to a target price to make the concept we developed a viable one. Unidrive’s new and improved packaging provides long-term production protection, as well as safe, ergonomic, user-friendly packaging for their operators.

At PPI, our knowledgeable team of onsite packaging designers and engineers will create customised logistics packaging or display solutions to meet the specifications of your product. We also offer storage and stock fulfilment services to suit your packaging supply needs. You can find out more about our services here.

With complete, in-house design, manufacturing and fulfilment capabilities, we work in partnership with your business to engineer your perfect packaging outcome. Questions? Call us now on 1800 25 8000 or connect with us to book your free initial packaging consultation.

Recent case studies

Case study

Reinventing the Cardboard Coffin with Smart Design

Introduction Printegrity Group is a combined marketing and print production facility with more than 25 years’ experience. They supply point of sale ...

More

Case study

Custom Packaging for Unique Gift Hampers

Beyond the Wooden Door is a mother-daughter business based in Melbourne with over 15 years of experience creating unique, consciously made gift hamper...

More

Case study

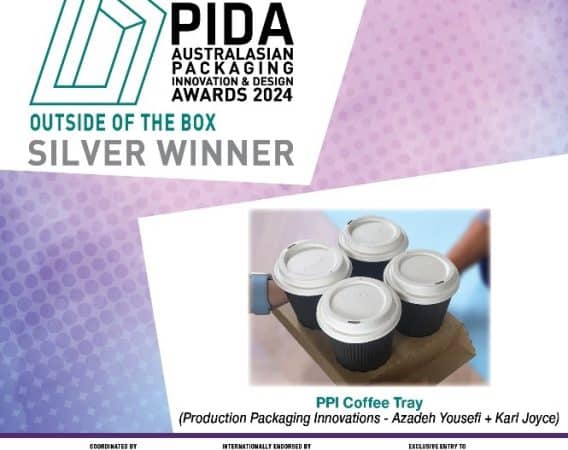

PPI’s PIDA Nominate Coffee Trays – changing and safeguarding the way of takeaway coffee

Coffee has kept up with the changing lifestyle and commuter culture which demanded and (therefore) led to the invention of cardboard coffee holder tra...

More